Introduction

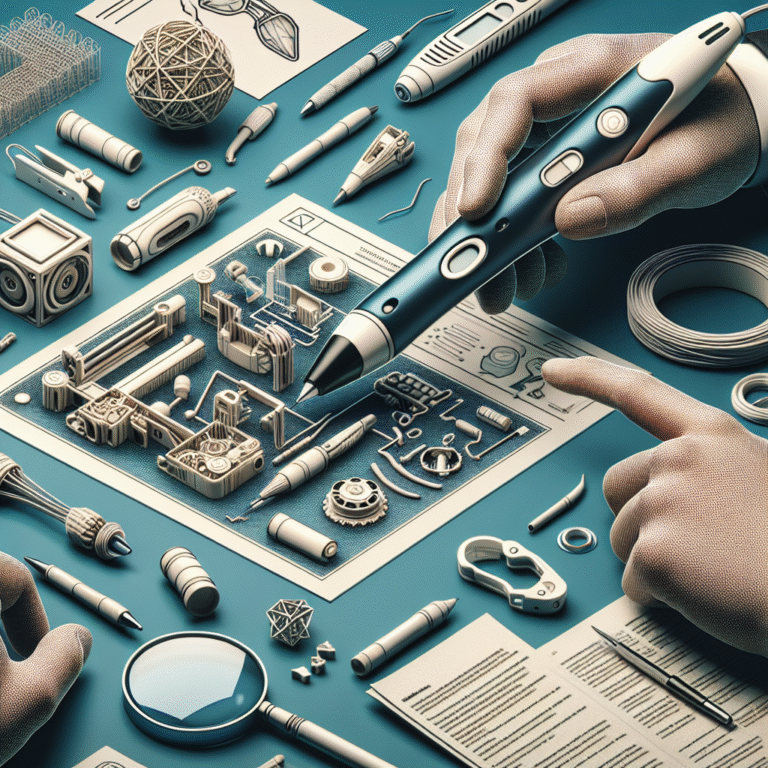

3D pens have revolutionized the world of crafting, enabling artists and hobbyists to create fascinating 3D structures with ease. However, like any technology, they can sometimes experience issues. One common problem is when a 3D pen stops extruding filament. Understanding the causes and solutions for this issue can save time and enhance your creative experience.

Common Causes of 3D Pen Extrusion Issues

Before tackling the issue, it’s essential to know the possible reasons why your 3D pen might stop extruding filament. Here are some common causes:

- Clogged Nozzle: Debris or cooled filament may be blocking the nozzle.

- Filament Jam: Filament could be tangled or jammed inside the pen.

- Temperature Issues: The temperature might be too low or too high.

- Power Supply Problems: An inadequate power supply can affect extrusion.

- Filament Quality: Low-quality filament might not extrude properly.

Troubleshooting Steps

If your 3D pen stops extruding filament, follow these troubleshooting steps:

Check the Power Supply

Ensure your 3D pen is properly connected to a power source. Look for loose connections or damaged cables. A steady power supply is crucial for consistent extrusion.

Inspect and Clean the Nozzle

A clogged nozzle is a frequent issue. Here’s a step-by-step guide to clean it:

- Turn off and unplug the pen.

- Let it cool down completely.

- Use a needle or a thin wire to gently dislodge debris from the nozzle.

- Once cleaned, reconnect and test the pen.

Check Filament Feed and Quality

Ensure that the filament is not tangled or jammed in the pen. Additionally, using high-quality filament can prevent extrusion problems. Below is a table comparing different filament qualities:

| Filament Type | Quality | Issues |

|---|---|---|

| PLA | High | Rarely clogs |

| ABS | Medium | Prone to warping |

| Low-Quality PLA | Low | Frequent clogs |

Adjust the Temperature Settings

Different filaments require different temperatures:

- PLA typically extrudes at 180-220°C.

- ABS extrudes at 220-250°C.

Consult your 3D pen’s manual for the recommended settings for your filament type.

Unjam the Filament

If the filament is jammed, follow these steps:

- Turn off and unplug the pen.

- Remove the filament.

- Reload the filament according to the manufacturer’s instructions.

Preventive Measures

- Regular Cleaning: Regularly clean the nozzle to prevent clogs.

- Use High-Quality Filament: Investing in good quality filament reduces the risk of jams and clogs.

- Proper Storage: Store filament in a dry, cool place to maintain its quality.

- Regular Maintenance: Follow the maintenance guidelines provided in the pen’s manual.

Conclusion

When your 3D pen stops extruding filament, it can be frustrating. However, by understanding the common issues and following the troubleshooting steps provided, you can quickly get back to your creative projects. Remember to keep your pen and filament in good condition to avoid future issues.

Leave a Comment