Introduction

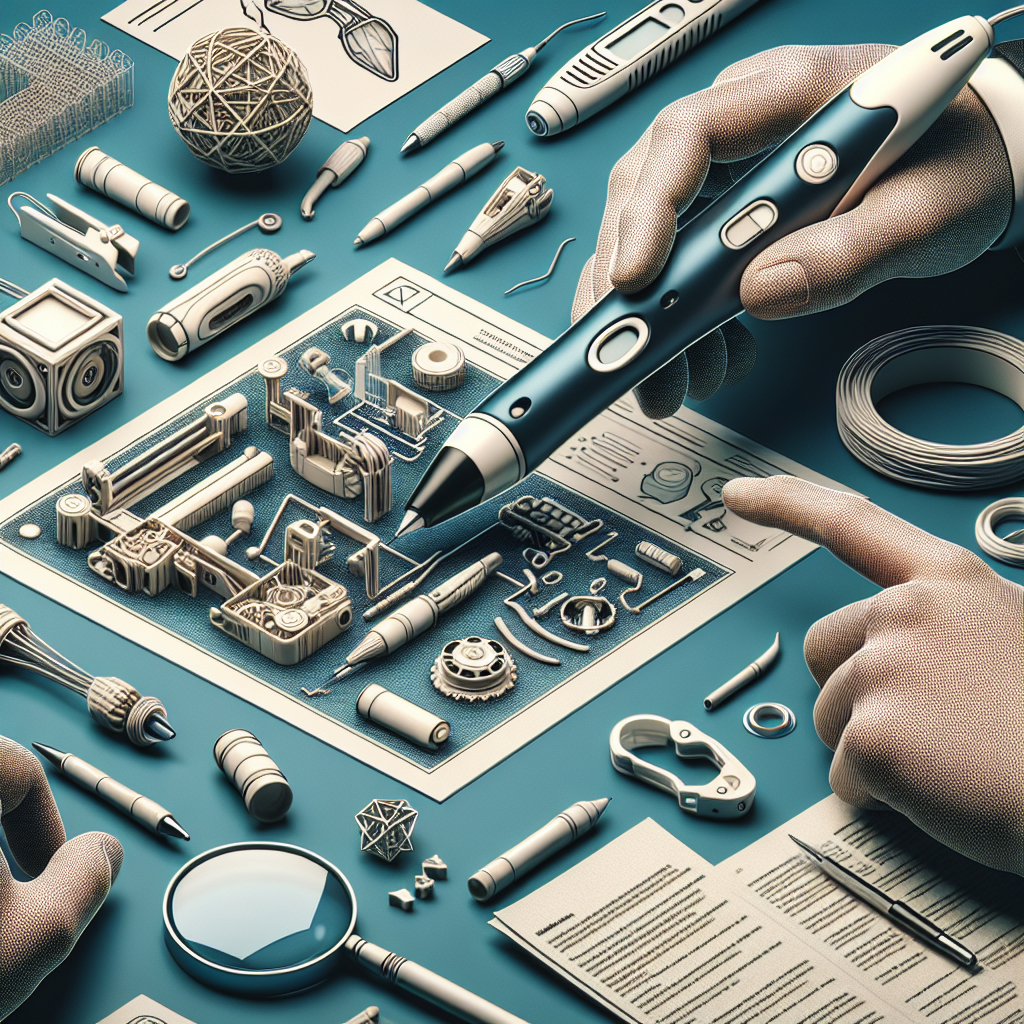

3D pens have revolutionized the world of crafting and prototyping, allowing users to bring their ideas to life with ease. However, like any other piece of technology, 3D pens are not devoid of issues. Understanding how to troubleshoot common problems can save time, reduce frustration, and ensure you achieve the best results. This article will provide you with a comprehensive guide on how to troubleshoot common issues with a 3D pen.

Common 3D Pen Issues and Troubleshooting Tips

The table below highlights common issues faced by 3D pen users and their possible solutions.

| Issue | Possible Cause | Solution |

|---|---|---|

| Filament Jam | Clogged nozzle | Clear the nozzle, use high-quality filament |

| Ink Not Extruding | Incorrect temperature setting, nozzle blockage | Adjust temperature, check for clogs |

| Overheating | Extended use | Allow pen to cool down |

| Poor Filament Quality | Substandard filament | Use branded, high-quality filament |

| Uneven Printing | Temperature fluctuations | Maintain a stable temperature |

| Poor Adhesion | Filament not adhering to surface | Prepare surface, use correct filament type |

Filament Jam

A filament jam is one of the most common issues users face. This often happens due to a clogged nozzle or the use of low-quality filament. To troubleshoot this:

- Clear the nozzle: Unload the filament and use a cleaning tool to remove any blockages.

- Use high-quality filament: Ensure you are using premium filament that fits your pen’s specifications.

Ink Not Extruding

If the ink is not extruding from your 3D pen, it could be due to incorrect temperature settings or a clogged nozzle. Here’s what you can do:

- Adjust temperature: Ensure the pen is set to the right temperature for the type of filament you are using. Different filaments require different temperatures.

- Check for clogs: If adjusting the temperature doesn’t help, inspect the nozzle for any clogs and clear them.

Overheating

Extended use of the 3D pen can cause it to overheat, potentially damaging internal components. To prevent overheating:

- Allow the pen to cool down: After using the pen for an extended period, turn it off and allow it to cool down before using it again.

Poor Filament Quality

Low-quality filament can cause a myriad of problems, including clogging the nozzle and producing uneven prints. To avoid this:

- Use branded, high-quality filament: Invest in reputable filament brands to ensure consistent performance and high-quality prints.

Uneven Printing

Temperature fluctuations can cause uneven printing, leading to a poor quality product. To maintain even prints:

- Maintain a stable temperature: Ensure your 3D pen maintains a constant temperature throughout the printing process.

Poor Adhesion

If the filament is not adhering to the surface you are printing on, this can result in failed prints or parts that do not come out as expected. To improve adhesion:

- Prepare the surface: Clean the surface and, if necessary, use adhesive aids like tape or glue.

- Use the correct filament type: Different surfaces might require different filament types to adhere properly.

Conclusion

Troubleshooting common issues with a 3D pen doesn’t have to be a daunting task. With the right knowledge and a bit of patience, you can overcome most problems and keep bringing your creative projects to life. Remember to regularly maintain your 3D pen, use high-quality materials, and ensure the correct settings to get the best results every time.

Leave a Comment